Mineral Insulated Cables, Manufacturer, Supplier, Exporter, Mumbai, Maharashtra, India |

Mineral Insulated

Cables (M.I. Cables) |

|

| |

| We introduce our latest addition in the cable line

which is the mineral – insulated, metal sheathed cable

products. The applications of MI Cable are many such as blast

furnace, atomic research, nuclear reactors, Kilns and many more. Our

product catalogue will help you in understanding and selecting MI

cables for your application requirements. We provide our customers

from standard as well as custom made products according to the needs

of the customer, our lines are flexible and ready to meet the

demand. |

| |

We manufacture cables in four

distinct product lines:

• Thermocouple cables for measuring temperature.

• RTD extension cables for use with resistance temperature

devices.

• Micro – Heater cables for unique industrial heating

applications.

• Mineral Insulated Power Cable Any Special Cable which requires

high

• temperature and rugged insulation |

| |

| Features of MI Cables |

| |

|

| |

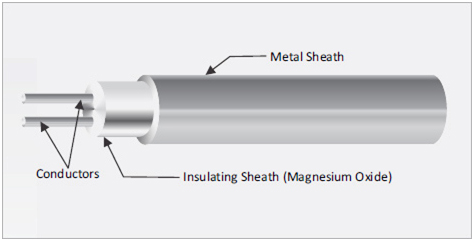

| Sheathed Thermocouple Cables have an outer sheath

of metal with Two to Eight Cores where positive and negative

thermoelements run around Circular Pattern , embedded in MgO.

Mineral Insulated Cables are suitable to high Mechanical, Chemical,

and Electrical stability. Due to good Flexibility, Excellent

mechanical strength, and pressure resistance, mineral insulated

Thermocouples/RTD's can be installed in complex installations. One

or more wire like conductors (cores) are embedded in a high

insulation quality MGO and pressed into a metal tube (sheath) made

of oxidation and corrosion resistant material. The entire

combination is then processed using suitable forming steps to obtain

the final dimensions. |

| |

• Mechanical Strength: The High Mechanical Strength

of MI cables can be attributed to the compact structure of MI Cables

consisting of densely packed insulation material MgO with tough

metal sheath which firmly places the conductors in the compound. The

banding radius in 3 to 5 times the outer diameter.

• Long Life: The manufacturing of MI Cables is such that it

ensures long conductor life as the sheath and insulation present in

the MI Cable help the wire stand against harsh environmental

conditions. This helps in the accurate calibration.

• Corrosion and Scaling Resistance:MI Cable manufactured in our

facility are corrosion and scaling resistant, so they can withstand

harsh or unfavorable environmental conditions.

• Long Length: We provide long lengths of MI Cable which were not

available in the past.

• Quick Response: Quick heat transfer takes place in the MI Cable

due to high thermal conductivity and small mass, which assures fast

and speedy response.

• Radiation Resistance: The Radiation Resistance feature of MI

Cables is a boon in application which involves high radiation. These

are widely used in the primary circuits and inside the core in the

reactors.

• Safety: The MI Cables are highly fire resistant due to the use

of insulation materials such as Mgo. These cables are highly

recommended from safety point of view.

• Moisture/Pressure: The homogeneity in metal sheath help the

cable to tolerate high external pressure by not allowing the flow of

majority of liquid and gaseous particles. |

| |

| Processing of MI cables |

| |

• Sintering Of MgO:Raw Mgo is hygroscopic, so it is

to be sintered to remove the moisture contents from MgO. Then MgO is

put inside the furnace at a temperature of 1280°C for around 5

hours.

• Drawing Of Sheath with Raw Materials: Reduce the diameter of MI

cable step by step. Employing special equipments.

• Annealing Of Cable:Annealing of MI cable in a furnace having

five zones at different temperatures depending on material types &

properties

Testing And Calibration :

• Calibration at three temperature point. • Insulation resistance

test. • Dimension test (conductor diameter, wall thickness, outer

diameter. • Loop resistance test. • Continuity test etc.

• Packaging and Storage: Storing in dry & dust free atmosphere

with proper tagging. The magnesium oxide insulation is hygroscopic.

To prevent moisture penetration, both ends are sealed. Under extreme

conditions some moisture absorption could take place in spite of the

sealing , so a dry place is desirable for storage. When pieces are

cut from stock lengths, the exposed ends to be sealed at once. If at

all Moisture has entered, this will lower the insulation resistance

and may prove troublesome in welding. Moisture Penetration can be

corrected by heating the sheath.

• Tagging: Each coil is fitted with a temporary seal to prevent

moisture ingress during storage and shipping. Each coil is tagged to

uniquely identify it for traceability purposes.

• Dispatch and Test Certificate |

| |

|

| |

|

|

|